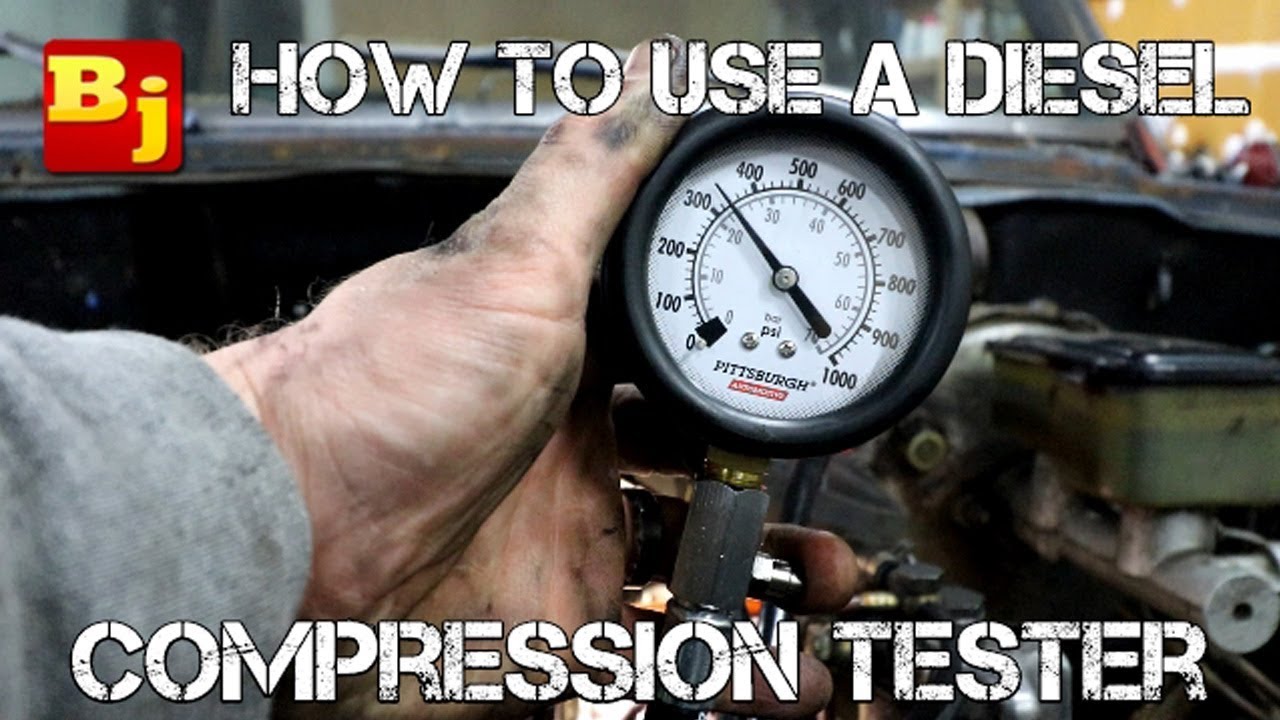

You can compression test the cylinders with the help of a compression gauge. Diesel engines require specialized equipment and an elaborate set up.

Some diesel engine manufacturers like Cummins dont provide compression numbers for diagnosing engine health but will use inches of blow-by measured by a manometer gauge Click to expand.

Diesel engine compression test procedure. Compression tests have always been a go-to for uncovering any issues that an engine might have and diesel engines are no exception to this rule. At first glance it seems like the testing procedure is very similar between gasoline engines and diesels however testing compression on a diesel does have different requirements procedures and. The engine compression test.

The testing procedure varies depending on the kind of engine you are using. However the overall process for most of the machines is the same. The following is the general procedure that one can use to.

Some diesel engine manufacturers like Cummins dont provide compression numbers for diagnosing engine health but will use inches of blow-by measured by a manometer gauge Click to expand. Yes they do a manometer wont tell you that you have zero or low compression due to a burnt valve head gskt etc which has nothing to do with blowby. To perform the compression test.

Remove all the glow plugs. If the engine is not equipped with glow plugs remove all the fuel injectors. Disconnect the fuel solenoid.

This prevents the cylinders from being washed down with fuel during the test. Connect a battery charger to the battery. This insures that the cranking speed.

ALH compression test procedure remove cover and dipstick. Warmup engine to at least 86 deg F30C disconnect the harness connector for the fuel cutoff valve aft of oil filter housing Disconnect glow plug harness. Blow area around glow plugs clean with compressed air.

10 MM socket remove all glow plugs. Lay out in order. Disconnect the ecm power.

Or if it is done through the glow plugs then remove all glow plugs. Remove the air filter. The engine needs to crank at 175 rpm 4 a minimum.

Record your readings on paper. Do not remove the injectors they test it through the glow plug hole. Remove all glow plugs.

Best done when engine is warm. Engine Testing and Instrumentation 9 Two cycle engines. BMEP HP 6500 L RPM psi 2-cycles require only one half of 4-cycle BMEP to produce the same power at the same rpm.

BMEP HP 13000 L RPM psi L Swept volume in Liters. 1 2-cycle one cylinder 80cc with 20 HP at 11500rpm. Today we use a Harbor Freight diesel compression tool to see the condition of our Mercedes Turbo DieselInstagram.

Put your compression tester into the empty hole. The test can be done without a Shrader valve but most people recommended leaving the valve in the gauge and burping the gauge every 5-6 puffs. Start the engine and take a reading.

Now goose the throttle for a snap acceleration reading reading should rise. Video of how to use Diesel engine compression Tool for test of Diesel engine. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy.

Diesel engines require specialized equipment and an elaborate set up. Testing a gasoline engine is rather simpler. There are two general ways of testing the compression on a gasoline engine.

The process involves the use of a manual hand-held compression gauge. â The test must only be done on a properly warmed up engine. Compression Test Your Diesel Engine.

Leakdown Test Your Diesel Engine. A compression test is an extremely important engine diagnostic procedure. It should be done on any diesel you are planning to purchase.

More than any other test it can tell you if you are purchasing a healthy engine. The test should also be done anytime you are experiencing engine performance problems. You can compression test the cylinders with the help of a compression gauge.

All you have to do is connect the gauge in place of a spark plug and test each cylinder pressure in turn. Once you have the results you compare your gauge reading to. A diesel compression test is an extremely important engine diagnostic procedure.

It should be done on any diesel you are planning to purchase. More than any other test it can tell you if you are purchasing a healthy engine. The test should also be done anytime you are experiencing engine performance problems.

Measurement of compression of a gasoline and diesel engine. Compression measurements on gasoline and diesel engines are different. In the first case the procedure is much easier than in the second.

The difference is as follows. The pressure in this case will be measured through the candle holes. The Laser Diesel Engine Compression Test Kit 2596 is a comprehensive tool kit for checking the condition of diesel engines on most cars and small boats fitted with diesel engines.

It tests for compression loss resulting from worn valves and valve seats valve guides piston rings cylinder head and gasket seals. Compression Pressure Test. To do a compression test the fuel injector will need to be removed and the compression tester installed Set the parking brake and chock the tires.

To do this procedure coolant temperature must be between 70-95C 158-203F. You need a special compression tester for diesel engines. Standard gasoline engine testers dont go high enough.

The proper tool should thread in place of the fuel injection nozzles and Jdc already stated the proper readings. However any cylinder that reads more than 30-40 psi different from the rest has a problem. They are also compression test machines available for diesel engines.

A selection of these is shown below with a few descriptive notes and prices. Direct Compression Test Kits. Petrol Engine Compression Test Kit 6 pc Sealey CT955.

Pressure gauge 212dia calibrated to 300 psi and 20kgcm. Engine Testing and Instrumentation19. The energy balance of a 75kW turbocharged diesel engine is as follows.

Fuel 17653kW Power 75kW 422 Heat to coolant 33kW186 Heat to oil 45kW 25 Heat to exhaust 531 kW 299 Convection radiation11kW 68 TOTALS 17653kW 17653kW.