YELLOW BORDER OR ELEVATED. CASTROL DURATECES Bureau Veritas - Oil Analysis 12715 Royal Drive Stafford TX 77477 800 - 248 - 7778 Page.

But the value of monitoring the oil remains.

Diesel engine oil analysis interpretation. Ad Short delivery times and custom tailored solutions. And so it is for diesel engines. Used Oil Analysis is one of the important and maybe the simplest approaches to diagnosing the health of an engine.

It is however not easy for engine users or engineers to understand and interpret each analysis parameter correctly and to. On your report you will receive a spectrochemical readout of a battery of elements which represent the wear metals of your engines components elements associated with the presence of. The oil wetted areas of the engine.

It also includes burnt lubricating oil and additive ash rust salt wear debris and abrasive matter. Increases may be due to the amount of blow by and sudden increases may indicate piston ring collapse or breakage. The limiting values for total insolubles that are set by the engine manufacturers are dependent.

Analyzing an oil analysis report involves understanding the concentration of expected and unexpected elements in your oil. Some contaminants are picked up as the oil circulates and splashes off different machine components and surfaces. The analysis will tell whether the oil has experienced excessive water contamination.

The lab may also look at the acid and base numbers. Acid levels indicate the extent to which the oil is overheating or oxidizing. The base number measures the alkaline reserves in the oil which offset the acid and help prevent corrosion.

Acid number measurement is now replacing TBN along with oxidation viscosity and wear metals to monitor diesel engine oil condition Diesel that once contained up to 500 ppm of sulfur led to the sulfuric acid that damaged bearings Granger explains. Todays limits are closer to 15 ppm. But the value of monitoring the oil remains.

Typically when copper and lead are present in an oil analysis report it is an indication of bearing wear. Determining whether it is justified to remove the engine and rebuild will require further investigation. Just one oil sample rarely provides enough information to make a diagnosis.

Interpretation of the test results with well-informed actionable maintenance or diagnostic. Oil analysis can be applied to equipment and lubricant utilization maintenance and management. The biggest concerns for engine health in heavy duty applications.

Coolant in engine oil Abnormal noise on operating at stall speed Lead Pb 40 - 100 ppm Bearing corrosion Extended oil change intervals Aluminum Al 10 - 30 ppm Piston and piston thrust Bearing wear Blow-by gases Oil consumption Power loss Abnormal engine noise Table 5. Engine Problems Analyzed through Oil Analysis 3. NATURAL GAS ENGINE Cummins ISL-G 2134108 Engine Fluid Mfr.

Fluid Brand Product. CASTROL DURATECES Bureau Veritas - Oil Analysis 12715 Royal Drive Stafford TX 77477 800 - 248 - 7778 Page. 1 of 2 VISCOSITY 100 C.

Oil Analysis Report Explained Page 3 of 3. Oil analysis provides fact-based information on the oils condition which can then be used to determine the engines condition. The data will help answer questions such as is the oil and filter change interval appropriate is there coolant fuel water or dirt in the oil and is the oil viscosity within appropriate limits.

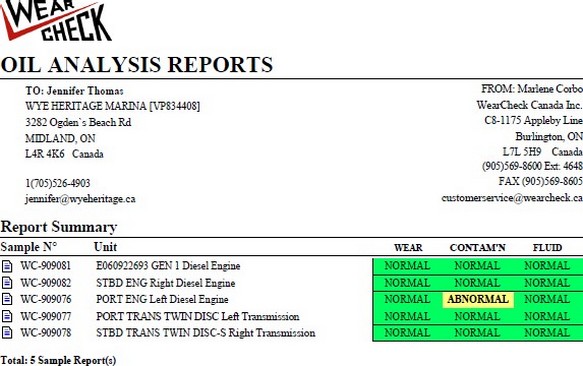

If youre considering buying a used vehicle a car a truck a motorcycle or even a piece of diesel construction equipment can be quickly given the oil analysis test to see what kind of shape theyre really in beneath their flawlessly washed and waxed exteriors. An engine oil analysis can give you a look deep inside the workings of the engine without you having to take it apart. The green border color indicates that these values are within a normal range compared to other engines like yours.

They are below the Caution level settings for your engine model engine hours and cylinder type. No corrective action is indicated based on these values. YELLOW BORDER OR ELEVATED.

Common abnormal conditions that arise include diesel engines showing increased levels of silicon and iron but failing to reach oil analysis alarm limits. Or hydraulic oil analysis results showing an increase in water and copper which can be a precursor of a future pump or valve failure. Many may get worse.

Oil analysis brings them to your attention so that doesnt have to happen. Act promptly on the information to take care of your equipment and reduce the risk of costly problems down the road. Were Here To Help.

Isel offers oil analysis to all users of lubricants manufactured by Isel. This service is designed to help you get the most out of your Isel lubricants protect and prolong the life of. For those who have not seen an oil analysis report this 11 page one includes analysis of generator oil both engines and the lube from both gear reduction unitsThis report is pretty typical and clearly shows why you may need to hire a qualified diesel mechanic to help interpret.

So you may save the cost and time of an oil analysis by simply pulling the dipstick and taking a look. An oil analysis report contains a lot of data that can tell you a lot about your equipment lubricant and processes. Each of the items detected can help you determine what contaminants have infiltrated your system.

Cylinder Oil Drain Engine Performance Analysis Condition Monitoring and Maintenance Planning for 2-stroke marine diesel engines Terence MCGeary Managing Director Flame Marine Limited 29 The Gill Ulverston LA12 7BP UK Tel. 44 1229 588601 Fax. 44 1229 587959 e-mail.

Diesel engine oil analysis is an economical method of monitoring engine health and lubricant condition. It will help identify factors that are detrimental to your engines performance and lifespan. Oil analysis provides data that show root causes or symptoms of issues that can cause lower performance or failure.

ENGINE OIL ANALYSIS WITH PRE-PAID MAILER - CC2528 This kit includes all tests necessary to evaluate engine wear and contamination for all types and makes of enginesThis kit does not evaluate the condition of the lubricant itself. Spectro-Analysis of 24 metals Fuel dilution Soot Contamination Percent of water contamination. Oil analysis can help improve two important considerations faced by fleet owners.

Fleet efficiency and fuel consumption. In December 2016 the industry welcomed the introduction of the API CK-4FA-4 heavy duty diesel engine oil categories which aimed to address these challenges. Ad Short delivery times and custom tailored solutions.