Or there might be a broken or disconnected wire inside. If the horns do not operate leave the 2 terminal connected to ground and connect a voltmeter from the 3 terminal to ground.

Remove the horn button.

Horn clip stuck in wires. Disconnect the horn itself. If your car has no relay and the horns fuse is on the same circuit as other important components remove the horn itself. This is located under the hood usually behind the front grille or attached to the firewall behind the engine.

The horn is typically shaped like a loudspeaker or a toroid doughnut. Disconnect the wires leading to the horn. When you hit the button it reconnects the relay and turns the horn on so long as its still jammed of course.

Clip the wire hook a new wire to each clipped end and run them both in the car and hook both to a cheap push button I just used crimp connectors with some dielectric compound in there and heat shrink tubing around it. My Ford E series van horn got stuck on. This video shows how and what tools you will need to take apart diagnose and repair the issue.

I took the steering w. If the horns operate check the 2 terminal wire and horn switch for defects. If the horns do not operate leave the 2 terminal connected to ground and connect a voltmeter from the 3 terminal to ground.

If a reading is obtained check the horn wiring and horns for defects. If no reading is obtained replace the horn relaybuzzer. One problem with removing the fuse for the horn is that this same fuse may also be on the same circuit for another electrical component.

Hence while silencing the horn you may be eliminating another accessoryfeature. This may involve something trivial or it could involve some function that is important. Let me give you an example.

Some issue with the horn circuit or switch. Continuously blowing horn for at least 2 and a half hours. Owner probably came back to a dead truck.

For the larger connections MAF or coil use a large paper clip. For the smaller connections temp sensor use a small paper clip. Start by flattening the ends with a hammer or vise grips.

Then curve the clip around till the two ends are a few mm apart. Introducing iJDMTOYs 12V horn wiring harness relay kit for grille mounted blast tone horns. From behind the ring.

On the 56-57 turn the horn ring counter-clockwise and remove it. Remove the turn signal lever by turning it counter-clockwise. Disconnect the horn wire at the connector to the wire loom in the engine compartment on the left apron and remove the wire from the steering shaft.

From these symptoms it appears that the horn itself is okay and that the horn wire at the back of the airbag has come out of its holder or one of the wires is loose or broken. To check this the airbag will need to be removed. The horn wire will be visible and how it clips into the steering wheel can be seen.

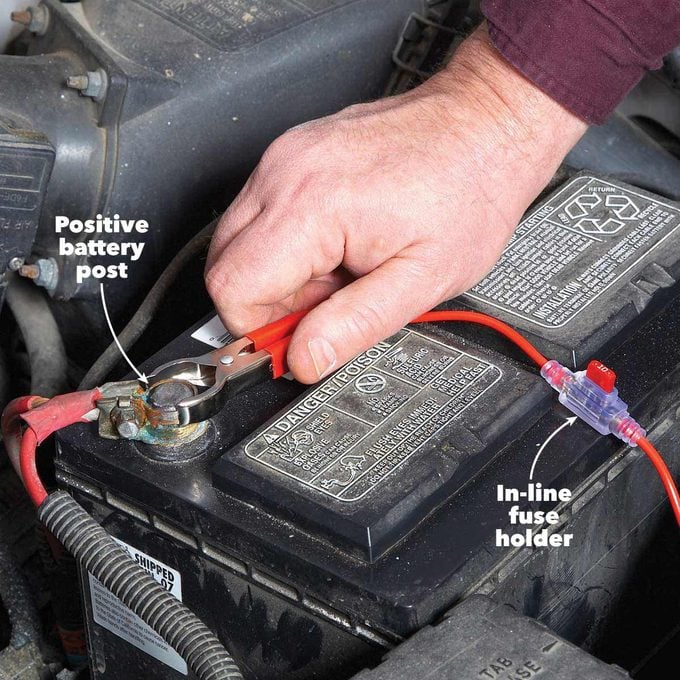

Repair the ground connection or wire as needed. Look at the two male terminals inside the connector of each horn. Clip one end of a test lead to the pin that receives power when the horn is activated.

Connect the opposite end to the positive battery terminal. Clip one end of a second test lead to the negative battery terminal. Danchuk 1955-1956 Chevy Horn Cap Emblem w Clips 210 V8.

Partially lift the horn button off the steering wheel and disconnect the wire leads. Remove the horn button. Once the wire leads have been disconnected lift the horn button off the steering wheel completely.

Part 2 of 2. Installing the new horn switch. Mount the new horn switch.

Loosely place the new horn switch in position on the steering wheel. Reconnect the wire leads. Reinstall any electrical connections into the horn.

Once youve verified that the horn is getting power use a test lead a piece of wire with two alligator clips at either end clipped to the brown wire on the horn. Then touch the other clip to the horn bracket mounting bolt or other suitable chassis ground. The horn should honk if not your horn.

Wiring a car horn to your bike - YouTube. Notice the black wires going to the horn button are used to ground the horn relay which will sound the horns. When working around the air bag circuit be sure to disconnect the negative - battery cable first then the positive.

HttpsgooglKrWHhzBucks Stuck Together Untangled by Farmers Two deer were stuck together by their antlers until these people ca. I wired up the horn to the brake switch and the gas boy at work actually drove the truck to quik trip with everyone staring at himTo use this video in a co. But an inoperative car horn can also be caused by a bad horn switch in your steering wheel a broken clock spring under the steering wheel a bum horn relay a broken wire or a corroded ground.

Heres how to check the most likely suspects. Start by checking the fuse. Refer to the owners manual for its location.

If the fault is in the horn itself you may be able to dismantle the horn and find what is wrong. Cleaning the contact breaker might work. Or there might be a broken or disconnected wire inside.

Horns that are riveted together cannot be dismantled easily and must be replaced with new ones.