Run engine at 2000 RPM with all lights blower motor radio etc. The voltage drop measurement.

Since electronic components may be sensitive to test voltages do not perform any tests on circuits unless directed to do so in the appropriate Service Information.

How to do a voltage drop test. If you find a voltage drop move the negative lead to the next connector connection or component in the circuit and run the test again. Changes in the Voltage Drop Reading indicate where excessive Voltage Drop is located. We can test the negative side of.

Voltage drop should be checked with the circuit loaded and a fully-charged b. Voltage drop testing allows the technician to monitor voltage loss in a circuit. Drop Reading indicate where excessive Voltage Drop is located.

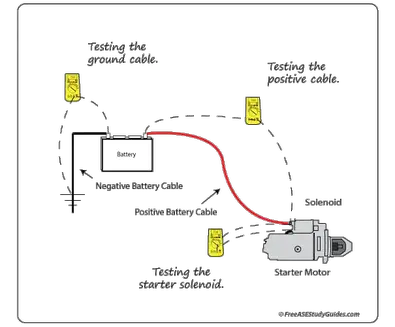

To test for a Voltage Drop on the Ground side of a circuit figure 2 follow the steps below. 1 Connect the negative test lead of a Digital VoltOhm meter DVOM to the negative battery terminal. Performing a voltage drop or volt drop test is the best way to check wiring.

If you are checking wiring for power checking for ground or an open you can. First check the entire positive side of the charging circuit for excessive voltage drop. Hook your meters positive lead to the alternator output stud and your negative lead to battery positive post.

Run engine at 2000 RPM with all lights blower motor radio etc. Answer 1 of 2. Easy you do a voltage drop test to measure either very small or high resistance accurately you set your bench power supply to constant current depending on application this can range from a couple of ma to tens of amps and measure the voltage across the resistance you wanna me.

To do a voltage drop test you create a load in the circuit thats being tested. Then you use a digital volt meter DVM to measure the voltage drop across the live connection while it is under the load. Voltage always follows the path of least resistance so if the circuit or connection being tested has too much resistance some of the voltage will flow through the DVM and create a.

The voltage drop measurement. To configure a multimeter to measure voltage drop you set it up the same way as you would any other voltage measurement. Put the black probe in the socket labeled COM for common meaning its common to all measurements.

Once its there itll never need to be moved. How do you test for voltage drop. To check the entire circuit connect the meter positive lead to a clean spot on the starter motor case and the meter negative lead to the negative battery post.

Crank the engine and note the reading. In order to perform a voltage drop test voltage must be present in a circuit. Its the difference between voltage at the source or battery and the voltage at the component.

The meters leads are connected in parallel with the circuit being tested. Its common to perform a voltage drop test on the starter circuit. To test the Power side of a circuit for voltage drop Figure 1 follow the steps.

Connect the positive test lead of a digital volt meter to the power source. Connect the negative - test lead to the other end of the wire of the component. What is a voltage drop test.

This is a way to troubleshoot an electrical problem that doesnt require disassembly and will show in little time whether your connection is good. To do it YourMechanic creates a load in the tested circuit and use a DVM digital volt meter to measure the voltage drop while the connection is under load. During this test notice at which point voltage drop goes down to an acceptable level.

Your trouble point will be the previous one to this point. Move the voltmeter red lead to the alternator mounting bracket. Keep the meter black lead on the battery negative post and take a note of your reading.

Using your multimeter DVOM or digital volt ohm meter to scope out excessive voltage drop. Diagram from one of the authors books Advanced Marine Electrics and Electronics Troubleshooting We received a question from a reader the other day asking about how they might go about checking for excessive voltage drop on their boat. Good question that needs a bit of.

How to perform a voltage drop test on your battery alternator starter cables. Rule out possible battery cable issues when troubleshooting a bad alternat. To do a voltage drop test you create a load in the circuit thats being tested.

To take a look at the starter circuit for excessive resistance you want to degree the voltage drop on the battery battery cable connections and starter even as the engine is being cranked. Since electronic components may be sensitive to test voltages do not perform any tests on circuits unless directed to do so in the appropriate Service Information. Voltage drops must be measured in a live functioning circuit with current flowing.

If there is an open the voltage drop reading is meaningless. Mastering Voltage Drop Testing with Pete Meier and G Jerry Truglia - YouTube. To do a voltage drop test you create a load in the circuit thats being tested.

You then use a digital volt meter DVM to measure the voltage drop across the connection while it is under a load. 10 If a connection is good you should find little or no voltage drop. If you find a voltage drop of more than 1.

Using a digital multimeter is the fastest way to accurately measure voltage drop. If the digital multimeter you own does not have auto-ranging capability use a low-voltage 0 to 1V scale for voltage drop testing. Remember that test lights are not accurate enough to diagnose electrical voltage drop and can damage most computer circuits.

Consult your repair manual if necessary. To find the wire connection or component with high resistance test wires and components in the circuit for voltage drop. Check for voltage drop between.

The positive battery post and the starting safety switch power output side first and then power input side.