First is to install the sensor. To avoid cutting or unsheathing the wire use a rubber grommet when passing them through a firewall or sheetmetal.

Attach the black lead on your meter to any good ground on the engine.

How to hook up a tachometer to a diesel engine. Before we go any further we recommend watching our installation video. It provides a clear demonstration of how to install our diesel tachometer. However generally speaking installing our diesel tachometer only requires two steps.

First is to install the sensor. How do you hook up a tachometer to an engine. Attach the tachometer ground wire to an engine ground of the car.

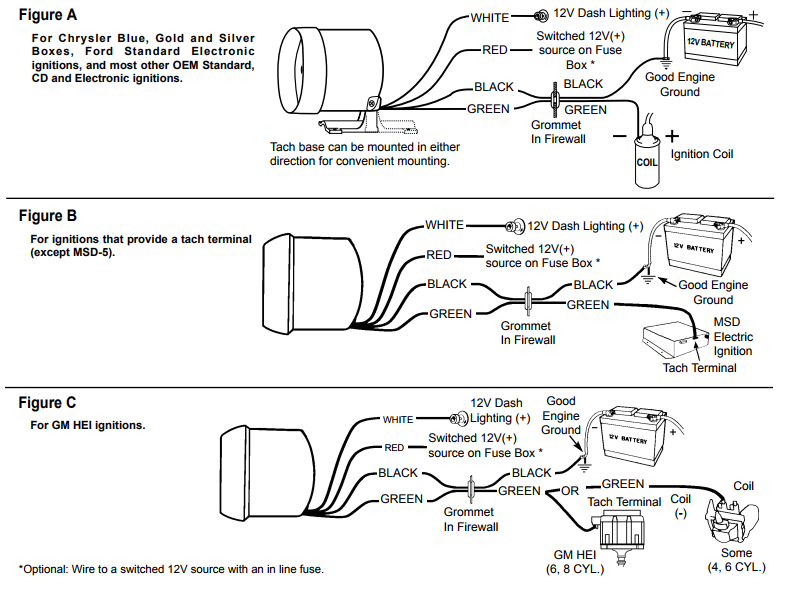

This need not be directly on the battery. Attach the tachometer pickup wire. The tachometer wire must be fed through a grommet in the passenger compartment to reach the engine compartment.

Diesel tach hook up - YouTube. Diesel tach hook up. If playback doesnt begin shortly try restarting your device.

The tachometer will have wires coming from the back of the gauge. One is a ground wire one is a power supply sire and one connects the vehicles ignition system either via the ignition coil or through an electronic connection with the vehicles computerized ignition. How do you hook up a tachometer to an engine.

The easiest way in many cases is off of the engines alternator. This is done by wiring a terminal into one of the leads on. Dakota diesel converter - The DSL-1 Universal Diesel Tachometer Adaptor will accept a signal from the W terminal found on some diesel alternators not all alternators used on diesel engines have this extra terminal and converts the signal into a tachometer signal for a 4 or 8 cylinder standard ignition system tachometer.

Because diesel engines dont have a coil to provide an ignition signal for the tachometer to measure we are forced to find other ways to get a signal thats proportional to engine rpm. One way to get a signal would be to use the P connection on the 140-amp CS144 alternators SFLP plug. The proper way to hook an aftermarket tach like the Autometer is to use the CTO clean tach output wire which is available under the hood on the passenger side near the windshield.

Ford specifically warns against tapping into the wiring coming from the PCM because any bad wiring or a fault in the aftermarket tach could fry the PCM. Stewart Warner Performance Diesel Tachometers must be calibrated after installation for accurate operation. See DIP-switch setting chart for additional applications.

Remove the 3 Torx screws using a T10 Torx driver. Start the engine and determine the actual engine RPM using a reference tachometer optical non-contact tachometer. Attach the black lead on your meter to any good ground on the engine.

That is an unpainted metal part. Step 3 Set the meter for the number of cylinders your engine has. Set the cylinder switches to match the number of cylinders in your engine.

Replace the end cap of the tachometer carefully to avoid pinching any of the internal tachometer wires. The best way on a diesel to ascertain shift ponts is via seat-of-the pants. When it stops pulling shift.

Academically it may be possible to put a tach on anything using workarounds. Just like it is possible to put a cruise control on one. But the RPM pulsed signal isnt there as a trigger.

CALIBRATION AND ADJUSTMENT The Tachometer is factory calibrated to - 3 Full Scale Accuracy. Provision has been made for finer adjustment if desired or synchronization of twin installations. This will require use of a Master Remote Tachometer.

Attach a remote master tachometer to engine to obtain true Rpm reading. Auto Meter Diesel Tachometers Connected To The Alternator Installation How-To Install - YouTube. Auto Meter Diesel Tachometers Connected To The Alternator Installation How-To Install.

This video demonstrates how to wire a tachometer on almost any vehicle with EFI. In this video I wired it up on a 1997 Toyota Tercel. Thread the magnetic pickup until it bottoms out directly on the centered flywheel tooth.

Once the pickup has bottomed out turn the pickup back out exactly one half turn or 180 degrees back out. Auto Meter gave us some other tach-installation tips too. Make sure your tach is set up for your engines cylinder count.

Youll often see an internal switch for 4- 6- or 8-cylinders. To avoid cutting or unsheathing the wire use a rubber grommet when passing them through a firewall or sheetmetal. I just got a diesel tachometer that uses a magnetic pickup to drive it.

Im planning on using the ring gear on the flywheel for the pickup to read. My question is how many teeth on the ring gear of a B5100 with a Z500 engine. I need the info to calibrate the tach.

The tachometer display reads 2. Now you must enter two values. One for the number of cycles in the engine you are using.

The second for the num-ber of cylinders in the engine. To program the tachometer for use with a 4-cycle 6-cylinder engine for example push.